Thrust Restraint Design

- Home

- Tools

- Thrust Restrain Design

- Vertical Offsets

The Viadux TYTON-LOK® System is well known for providing thrust restraint for rubber ring, TYTON JOINT, ductile iron pipelines. Full details of the TYTON-LOK restrained rubber ring joint system can be found in the Viadux Ductile Iron Pipeline Systems, Design Manual and Handling & Installation Manual. Key aspects only are highlighted below.

Benefits:

-

Eliminates thrust blocks –

- Valuable in congested service trenches.

- Eliminates waiting for concrete to cure.

- Convenient where concrete supply difficult.

- Useful in low bearing strength soils

- Alternative to use of flanged pipe in buried applications

Limitations:

- The TYTON-LOK system is not suitable for above ground applications.

- TYTON-LOK joints are not suitable for use with PN20 pipe. Use only with PN35, lange class, K9 or K12 pipes.

- A combination of TYTON-LOK joints and thrust blocks where both contribute to the overall restraint of the system, is not recommended.

- TYTON-LOK is not suitable for use on Fusion Coated pipe or fitting spigots.

- The Maximum Allowable Operating Pressure should not exceed 1.6 MPa.

- TYTON-LOK rubber rings are only available in sizes DN100 - DN375.

Important Notes on Use:

- TYTON-LOK gaskets should only be used with genuine Viadux TYTON brand pipes, fittings or valves. Do not use with other DI sockets.

- Do not use TYTON-LOK gaskets with pipe materials other than Ductile Iron.

- Marking tape is required for identification of restrained sections of pipelines. Use pink coloured polyethylene tape approximately 100mm wide, with the inscription:

"WARNING - RESTRAINED PIPELINE - USE RESTRAINED FITTINGS ONLY" - Do not use with cut pipe lengths less than 20 times DN, measured in millimetres, for DN 100 to DN 250. For DN 300 and 375, full pipe length only should be used.

- Complex arrangements of fittings in close proximity to each other should be flanged.

- Incorrect installation or application of TYTON-LOK joints can result in serious injury.

Assembly:

- Joining shall be in accordance with the Viadux Ductile Iron Pipeline Systems Handling & Installation Manual.

- Prior too inserting the TYTON-LOK gasket, the socket should be checked for cleanliness and any dust, dirt, debris, inclusions or foreign material should be removed from the socket anchor groove and sealing chamber.

- When looping the gasket for insertion, the inner loop should be positioned between locking segments.

- Lubricate the TYTON-LOK gasket after being placed within the socket and 25mm of the spigot to be inserted.

- Where joint deflection is required, insert the spigot to the first witness mark only and then deflect the joint. The joint will not deflect after inserting the spigot all the way home.

- Joints should be backed off after assembly to ensure that gasket teeth have locked properly.

- Pipelines using TYTON-LOK gaskets should be completely bled of air before application of the field test pressure.

Disassembly:

- Joints to be disassembled in accordance with the Viadux Pipeline Installation Manual.

- Do not re-use TYTON-LOK gaskets.

- BENDS

- TEES

- REDUCERS

- DEAD ENDS

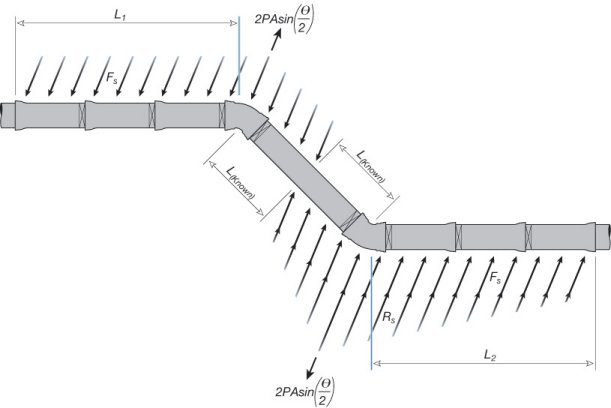

- VERTICAL OFFSETS

- COMBINED HORIZONTAL BENDS

- COMBINED VERTICAL EQUAL ANGLE OFFSET UNDER OBSTRUCTION

- COMBINED VERTICAL EQUAL ANGLE OFFSET OVER OBSTRUCTION

Suggested Values for Soil Parameters and Reduction Constant, Kn

| Lookup | Soil | Laying | f | ff | Cs | fc | γ | Kn | fc*Cs =C | ff*f |

|---|---|---|---|---|---|---|---|---|---|---|

| Code | Designation | Condition | (degrees) | kPa | kg/cum | MPa | ||||

| Clay 1 - LT 2 | Clay 1 | 2 | 0 | 0.00 | 14.36 | 0.50 | 1,442 | 0.20 | 0.00718 | 0.00 |

| Clay 1 - LT 3 | Clay 1 | 3 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 0.40 | 0.01149 | 0.00 |

| Clay 1 - LT 4 | Clay 1 | 4 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 0.60 | 0.01149 | 0.00 |

| Clay 1 - LT 5 | Clay 1 | 5 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 0.85 | 0.01149 | 0.00 |

| Clay 2 - LT 2 | Clay 2 | 2 | 0 | 0.00 | 14.36 | 0.50 | 1,442 | 0.40 | 0.00718 | 0.00 |

| Clay 2 - LT 3 | Clay 2 | 3 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 0.60 | 0.01149 | 0.00 |

| Clay 2 - LT 4 | Clay 2 | 4 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 0.85 | 0.01149 | 0.00 |

| Clay 2 - LT 5 | Clay 2 | 5 | 0 | 0.00 | 14.36 | 0.80 | 1,442 | 1.00 | 0.01149 | 0.00 |

| Coh-gran - LT 2 | Coh-gran | 2 | 20 | 0.40 | 9.58 | 0.40 | 1,442 | 0.40 | 0.00383 | 8.00 |

| Coh-gran - LT 3 | Coh-gran | 3 | 20 | 0.65 | 9.58 | 0.40 | 1,442 | 0.60 | 0.00383 | 13.00 |

| Coh-gran - LT 4 | Coh-gran | 4 | 20 | 0.65 | 9.58 | 0.40 | 1,442 | 0.85 | 0.00383 | 13.00 |

| Coh-gran - LT 5 | Coh-gran | 5 | 20 | 0.65 | 9.58 | 0.40 | 1,442 | 1.00 | 0.00383 | 13.00 |

| Good sand - LT 2 | Good sand | 2 | 36 | 0.75 | 0.00 | 0.00 | 1,602 | 0.40 | 0.00000 | 27.00 |

| Good sand - LT 3 | Good sand | 3 | 36 | 0.80 | 0.00 | 0.00 | 1,602 | 0.60 | 0.00000 | 28.80 |

| Good sand - LT 4 | Good sand | 4 | 36 | 0.80 | 0.00 | 0.00 | 1,602 | 0.85 | 0.00000 | 28.80 |

| Good sand - LT 5 | Good sand | 5 | 36 | 0.80 | 0.00 | 0.00 | 1,602 | 1.00 | 0.00000 | 28.80 |

| Sand Silt - LT 2 | Sand Silt | 2 | 30 | 0.50 | 0.00 | 0.00 | 1,442 | 0.40 | 0.00000 | 15.00 |

| Sand Silt - LT 3 | Sand Silt | 3 | 30 | 0.75 | 0.00 | 0.00 | 1,442 | 0.60 | 0.00000 | 22.50 |

| Sand Silt - LT 4 | Sand Silt | 4 | 30 | 0.75 | 0.00 | 0.00 | 1,442 | 0.85 | 0.00000 | 22.50 |

| Sand Silt - LT 5 | Sand Silt | 5 | 30 | 0.75 | 0.00 | 0.00 | 1,442 | 1.00 | 0.00000 | 22.50 |

| Silt 1 - LT 2 | Silt 1 | 2 | 29 | 0.50 | 0.00 | 0.00 | 1,442 | 0.20 | 0.00000 | 14.50 |

| Silt 1 - LT 3 | Silt 1 | 3 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 0.40 | 0.00000 | 21.75 |

| Silt 1 - LT 4 | Silt 1 | 4 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 0.60 | 0.00000 | 21.75 |

| Silt 1 - LT 5 | Silt 1 | 5 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 0.85 | 0.00000 | 21.75 |

| Silt 2 - LT 2 | Silt 2 | 2 | 29 | 0.50 | 0.00 | 0.00 | 1,442 | 0.40 | 0.00000 | 14.50 |

| Silt 2 - LT 3 | Silt 2 | 3 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 0.60 | 0.00000 | 21.75 |

| Silt 2 - LT 4 | Silt 2 | 4 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 0.85 | 0.00000 | 21.75 |

| Silt 2 - LT 5 | Silt 2 | 5 | 29 | 0.75 | 0.00 | 0.00 | 1,442 | 1.00 | 0.00000 | 21.75 |

Soils - Horizontal Bearing Strengths

| Soil Type | Description | Bearing | Strength |

|---|---|---|---|

| Sb(lb/sqft) | Sb(kPa) | ||

| 1 | Muck | 0 | 0 |

| 2 | Soft Clay | 1,000 | 48 |

| 3 | Silt | 1,500 | 72 |

| 4 | Sandy Silt | 3,000 | 144 |

| 5 | Sand | 4,000 | 192 |

| 6 | Sandy Clay | 6,000 | 287 |

| 7 | Hard Clay | 9,000 | 431 |

Type 1

Flat - bottom trench. Loose backfill

'Flat-bottom' is defined as undistrurbed earth.

For DN 350 and larger pipe, consideration should be given to the use of

laying conditions other than Type 1.

Type 2

Flat-bottom trench. Backfill lightly consolidated to centreline of pipe.

'Flat-bottom' is defined as undisturbed earth.

Type 3

Pipe bedded in minimum 100mm loose soil. Backfill lightly consolidated to top of pipe.

'Loose soil' or 'select material' is defined as native soil excavated from the trench, free

of rocks, foreign materials and frozen earth.

Type 4

Pipe bedded in sand, gravel or crushed stone to a depth of 1/8 the pipe diameter,

minimum 100mm. Backfill compacted to top of pipe.

Approximately 80% Standard Proctor, AASHTO T-99

Type 5

Pipe bedded to its centreline in compacted granular material, minimum 100mm under pipe.

Compacted granular material or select material to top of pipe.

Approximately 90% Standard Proctor, AASHTO T-99

'Loose soil' or 'select material' is defined as native soil excavated from the trench,

free of rocks, foreign materials and frozen earth.

Consult your Pentair Water Solutions Customer Centre for assistance if:

- The additional TYTON-LOK joints for a fitting encroach or overlap the additional TYTON-LOK joints for another fitting.

- Pipe other than 5.5 metre lengths is to be used either side of the fitting;

- Fitting is a 90-degree vertical bend.